Filtration

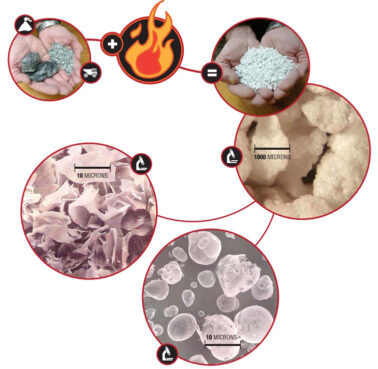

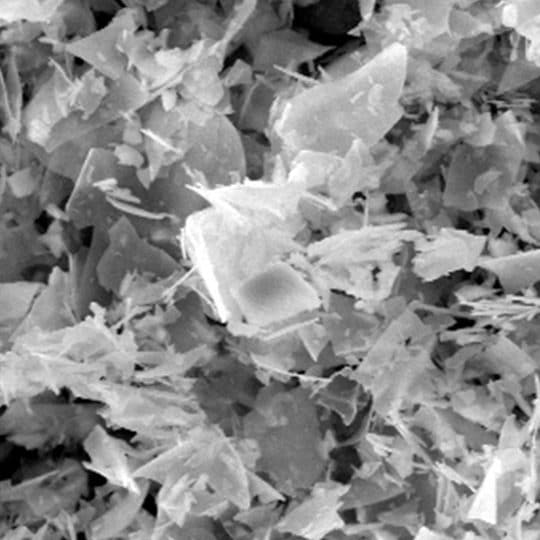

Lightweight expanded perlite bubble structures are milled and classified using strictly defined processes to produce perlite filter aids with specific flow characteristics. The various grades utilize the jagged interlocking structures to create billions of microscopic channels between the filter aid particles to produce optimum flow rates and clarification abilities for a wide variety of applications.

Learn More

Perlite in Filtration Industry

- Food and Beverage Industry: Ideal for clarifying hydrogenated vegetable oils, citric acid, sugars, and fruit juices, ensuring product purity and quality.

- Oil Filtration: Enhance the removal of impurities in edible and industrial oils with perlite’s exceptional filtering capabilities.

- Pharmaceuticals: Perlite filter aids are used in the pharmaceutical industry to clarify solutions and remove contaminants during the manufacturing process. The filtration step is critical because it helps to ensure that the final pharmaceutical products are free from particulates and microbial contaminants, which is essential for patient safety and drug efficacy. The inert nature of perlite means it does not react with the substances being filtered, preserving the chemical integrity of the pharmaceutical compounds.

- Glucose and Chemicals: In the production of glucose syrups and other chemical substances, perlite filter aids are used to remove impurities that could affect the quality and appearance of the final product. The fine filtration provided by perlite helps in achieving a high level of clarity and purity.

- Swimming Pool Water: perlite filter aids for sparkling clean pool water, providing an enjoyable and hygienic swimming experience.

- Industrial Wastewater Treatment: Perlite aids in the efficient purification of industrial effluents, supporting environmental compliance.

- Drinking Water Treatment: Use perlite for the filtration of potable water, ensuring safety and taste quality.

- Aquaculture: Maintain the clarity and quality of water in fishery and aquaponic systems with perlite filtration.

Benefits of Perlite in Filtration

- Naturally Inert: It has no taste, color, or odors that are transferred to the filtered product, preserving the purity of the substance being filtered.

- Insoluble: Perlite remains insoluble in mineral and organic acids at all temperatures, and its solubility in strong alkaline solutions varies with temperature and contact time, ensuring the stability of the filter media.

- Usable With Standard Equipment: Perlite filter aids are compatible with both pressure and vacuum filtration equipment, offering versatility without the need for specialized machinery.

- Less Weight, Same Volume: Perlite filter aids can be up to 50% lighter than other filter media types, reducing the weight of the filter cake without reducing volume, which can contribute to cost savings in handling and disposal.

- Anti-Caking: The end of the filtration process with perlite is efficient because the filter cakes remain porous and do not compact, facilitating easier cleaning and maintenance of filtration equipment.

- Cost-Effective: Switching to a perlite filter aid from other media is cost-effective and seamless, without compromising filtration performance.

- High Filtration Efficiency: Perlite traps particulates effectively, providing high clarity in the filtration of a wide array of liquids.

- Regenerative and Reusable: The potential to regenerate and reuse perlite makes it an economical choice for filtration operations.

- Sustainable: Using perlite aligns with green practices due to its natural origin and minimal environmental impact.

- Non-Toxic: Handling perlite poses no health risks, ensuring safety for workers and the environment.

- Broad Range of Applications: Perlite’s adaptability makes it suitable for diverse filtration needs across industries.

- Energy Savings: The lightweight nature of perlite aids in reducing energy consumption during the filtration process.

Applications of Perlite Filter Aids

Perlite filter aids have gained acceptance in almost every industry concerned with the separation of liquids and solids, and even gasses and solids. The following list, although not all-inclusive, gives an indication of the many applications where perlite filter aids are being used.

Food and Beverage

- Juices

- Sweeteners

- Vegetable oils

- Wastewater treatment

Industrial

- Water treatment

- Sizings

- Oil & solvent recovery

- Greases

Chemicals

- Inorganic & organic chemicals

- Resins

- Polymers

- Brine

- Adhesives

- Fertilizers

- Waste disposal

Paint & Coatings

- Waxes

- Oils

- Varnish

- Gums

- Shellac

- Wastewater treatment

Pharmaceuticals

- Enzymes

- Antibiotics

- Epsom salt

Environmental

- Stormwater filtration

- Ecology embankments

- Media filter drains

Technical Features

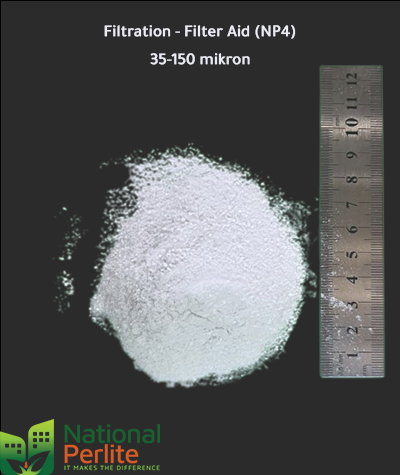

| Attribute | Values |

|---|---|

| Density | Weak Density 65-100 kg/m3 Squeezed density 125-140kg/m3 |

| Grain Diameter | between 35 mikron / 150 mikron |

| Porosity | % 85 |

| PH | 4 – 9 |

| Fusion Point | 1270-1295 |

| Chemical Composition | SiO2 % 74.00 Al203 % 14.33 K2 0 % 4.95 MgO % 0.28 CaO % 0.50 Fe2O3 % 0.97 |

| Humidity % | 0,1 |

| Color | White |

| Changeable Ions | meg/100gr Na+ 2.31-2.37 K+ 0.32-0.42 Ca+ 2.96-3.20 Mg+ 0.20-0.21 |

| Package | Packages with 20 kg of laminated print |

Why Perlite Is Effective: A Scientific Perspective

Perlite’s effectiveness is rooted in its unique physical properties. When heated to approximately 900°C (1,700°F), perlite’s volcanic glass softens, and its internal water vaporizes, causing an expansion that transforms the rock into a lightweight, porous material.

Versatile Functionality:

- Insulation: The expanded form of perlite consists of micro-bubbles, creating an insulative material that traps air and reduces thermal conductivity. This feature makes it ideal for insulation in the construction industry.

- Filtration: These same micro-pores effectively filter out impurities, making perlite an excellent filtration aid for liquids in various sectors, from food and beverage to wastewater treatment.

- Horticulture: In gardening and agriculture, perlite’s air pockets retain water and provide space for air, promoting root growth and improving soil structure without compaction.

- Industrial Uses: Perlite is also incorporated into lightweight plasters, concrete, and refractory materials, improving strength while maintaining a lighter weight.

- Consumer Products: Its gentle abrasiveness and absorbency make perlite a useful component in personal care products like exfoliants and a carrier in cleaning supplies.