Construction and Building Materials

In the realm of construction and building materials, perlite has established itself as a versatile component, essential for modern building techniques. It is a key ingredient in creating lightweight concrete, enhancing not only the insulating properties but also the structural integrity of concrete used in both readymix and precast applications. Beyond its role in concrete formulations, perlite is a favored choice as a loose-fill insulation material for concrete masonry blocks, enhancing thermal efficiency in cavity walls and residential homes. Its adaptability extends to specialty applications such as fireproofing sprays, chimney fills, interstitial floors, and acoustical treatments, offering solutions that meet the rigorous demands of the construction industry.

Learn More

Solutions for Advanced Construction and Insulation

Perlite in Lightweight Concrete, Ready-mix and Precast Concrete Applications

- Lightweight Concrete: Lightweight aggregate, enhances insulation properties of the concrete, making it both thermally efficient and fire-resistant, an edge in energy-saving solutions.

- Readymix Concrete: Enhance the workability and insulation of your ready-mix concrete with perlite, making it lighter and thermally efficient for a variety of construction projects.

- Precast Concrete: Perlite increases the structural integrity and thermal properties of precast concrete elements, providing a versatile solution. Perlite ensures lighter, thermally efficient components ready for quick assembly.

Perlite in Lightweight Formed Products

Over half of all the perlite expanded in the United States annually is used to make “formed products:’ These products include ceiling tiles, pipe insulation, roofing board and fire-rated door cores, and are manufactured with a variety of binders. Perlite formed products are the combination of perlite granules with binders such as fibers, hydraulic cement, plaster, sodium silicate, or even asphalt. These binders give the granules a portable, durable shape suitable for an intended use.

Enhancing Building Materials with Perlite

- Roofing Materials: Increase the lifespan and insulation of roofing systems with perlite, making them more energy-efficient and weather-resistant.

- Plasters: Perlite-infused plasters offer a smooth finish with improved insulation properties, ideal for both aesthetic and functional wall coatings.

- Ceiling Tiles: Perlite-infused ceiling tiles are not only aesthetically pleasing but also thermally and acoustically insulating.

- Fire Resistance: Our perlite products contribute to the fire resistance of building materials, creating safer structures that comply with stringent building codes.

- Fillers: Perlite serves as an inert filler, adding volume and improving the consistency of various construction materials without compromising quality.

- Plasterboard: Integrate perlite into plasterboard manufacturing for boards that are lighter, stronger, and offer better sound and fire insulation.

- Joint Compounds: Improve the bond and insulation of your construction joints with our premium perlite.

- Thermal Insulation & Fire Resistance Sprays: Perlite is infused in sprays for its excellent thermal insulation and inherent fire-resistant qualities, offering dual protection in one application.

Benefits of Perlite in Construction

- Superior Thermal Performance: High insulating values contribute to energy efficiency in buildings.

- Fire Resistance: Non-combustible nature offers superior fire ratings for safer construction.

- Lightweight Yet Durable: Facilitates ease in handling and longevity in structural applications.

- Smooth Slope-to-Drain Surface: Provides a monolithic surface for better water management on roofs.

- Versatile Roofing Material: Can be nailed or glued, offering flexibility in roofing applications.

- Wind Uplift Resistance: Meets Underwriters Laboratories (UL) and Factory Mutual (FM) criteria for wind uplift, enhancing building resilience.

- Innovative for Cellular Concrete: Improves cellular concrete through hybrid technology, adding to its strength and functionality.

- Cost-Efficiency: Realizes savings in time, labor, and materials, optimizing construction budgets.

- Acoustic Insulation: Reduces sound transmission for quieter indoor environments.

- Environmental Sustainability: Contributes to eco-friendly building practices and certifications.

- Versatility in Application: Perlite can be used in various forms, such as loose-fill, rigid board, and foam, offering flexibility in design and application for different construction needs.

- Compatibility with Other Materials: Perlite can be combined with cement, gypsum, and other building materials, enhancing its utility and functionality in composite systems.

- Ease of Handling and Installation: Due to its lightweight nature, perlite is easy to transport, handle, and install, reducing overall construction costs.

- Moisture Resistance: Perlite’s non-absorbent nature helps prevent moisture-related issues like mold and mildew.

- Chemical Inertness: Maintains performance in various environments due to its resistance to chemicals.

Perlite Uses and Applications as a Construction Insulating Filler

Nearly 50% of expanded perlite worldwide is used by the construction industry, largely in part because of its versatility. Some construction applications include:

- Aggregate in lightweight insulating concrete.

- Insulating and lightweight plaster.

- Loose fill insulation material for concrete masonry blocks, cavity walls, in residential homes.

- Fireproofing sprays.

- Chimney fills.

- Interstitial floors.

- Acoustical sprays.

- Green roof soils.

- Fireproof insulating door cores.

- Plaster Aggregate.

- Textured paint.

- Decorative stone.

- Tape joint compound.

- Cultured marble.

- Ceiling tiles.

- Underslab insulation.

- Cement stucco.

- And more.

Perlisoil P-12 Applications in Construction and Building Sector

Refractory Brick Production

PERLISIOL P-12 is integral to the advancement of brick production and soil mixtures. By introducing perlite as an additive agent for vessels, cementation, we enhance the performance of materials used in vessels and furnaces, from cementation to heat processing. This innovation not only contributes to fuel efficiency but also promotes the creation of bricks achieving higher heat isolation with lighter bricks.

Our PERLISIOL P-12-enriched product line includes:

- Ceramic-Bound Perlite Refractory Bricks: Combining the strength of ceramics with the lightness of perlite for high durability and thermal efficiency.

- Aluminum Phosphate-Bound Perlite Refractory Bricks and Concrete: These materials benefit from perlite’s insulative properties, offering improved resistance to thermal shock and structural integrity.

- Perlite Refractory Soil Mixtures: A tailored solution that utilizes perlite’s porous nature to enhance heat insulation in soil mixtures, providing a stable base for high-temperature applications.

Construction Heat Isolator Soil Mixtures and Plasters

PERLISIOL P-12 capitalizes on perlite’s natural heat and sound insulation properties derived from its porous structure, making it a choice material for plasters, roof coatings, schappe, and mortars. Its lightweight nature not only contributes to better thermal and acoustic isolation between floors but also reduces the structural load on buildings, enhancing earthquake resilience. Moreover, PERLISIOL P-12 retains its insulating properties under high-temperature conditions, supporting fire safety by preventing the spread of flames. This is due to perlite’s inorganic composition, which remains stable and effective even in intense heat.

Usage in Construction Sector

PERLISIOL P-12 serves diverse roles in the construction industry, optimizing materials and methods for enhanced building performance:

- Perlite Plasters: Crafted for superior finish and insulation.

- Lightweight Insulating Concrete: Perlite aggregates make concrete lighter and thermally efficient, ideal for both concrete and plaster applications.

- Light Structural Elements: Infusing perlite aggregates to create components that are robust yet light.

- Loose Fill Insulation: Employed as a non-compacting fill that provides excellent thermal and acoustic insulation.

- Floor Insulation: Perlite’s use in floor systems acts as an insulator, maintaining optimal temperatures.

- Specialized Concrete Mixes: Perlite replaces traditional binders in specific applications where lightweight and thermal properties are prioritized.

PERLISIOL P-12: Optimizing Horizontal Surfaces with Heat Isolating Soil Mixtures

For building material distributors and construction experts, PERLISIOL P-12 is engineered to perfect horizontal surfaces with its superior heat isolation properties. Before application, surfaces must be cleared of any unbound materials to ensure adherence. The area should be dampened prior to the application of the PERLISIOL mixture, which is then spread evenly at a depth of 3-3.5 mm. Careful smoothing with a spud and wooden trowel follows, without the use of rodding or surface vibrators, to create a seamless finish.

Post-application, the surface should be kept moist for 3 days to facilitate proper curing. After a period of 10-14 days, the PERLISIOL-treated surface will be ready to receive waterproofing treatments, ensuring a well-insulated and protected base layer. This meticulous approach ensures that PERLISIOL P-12 delivers on its promise of effective thermal insulation and contributes to the longevity of the construction project.

PERLISIOL P-12 Plastering: Enhancing Vertical Surfaces with Thermal Insulation

PERLISIOL P-12 emerges as a key player in thermal plastering for vertical applications, tailored for construction professionals and building material suppliers. To prepare for application:

- Clear the vertical surface of all loose material to ensure a pristine base for adhesion.

- For surfaces like Ytong blocks, apply a sand and cement mixture as an initial layer.

- The PERLISIOL soil mixture is then applied from the ground upwards in a smooth, singular motion to achieve a consistent first layer of 1-1.5 cm thickness.

- Allow this base layer to dry thoroughly before considering additional layers for increased thickness.

- Proper curing is critical; maintain a moist surface through watering for three days post-application.

This process ensures a level, thermally insulated wall surface, ready for finishing touches and capable of withstanding diverse environmental conditions.

Optimized Mixing Techniques for PERLISIOL P-12 in Construction

For Ready-Mix Concrete Suppliers and Building Material Distributors, achieving the perfect PERLISIOL P-12 mix is crucial:

- Maintain a cement-to-perlite ratio under 200 kg/m³ to ensure optimal insulation and weight characteristics.

- Mix thoroughly: Combine 300 liters of PERLISIOL (equivalent to three packages) with a 50 kg bag of cement for standard applications.

- Water ratio is key: Add 65-70 liters of water per mix in your concrete mixer, making sure not to exceed 300 liters per cubic meter.

- For sorbet production: Integrate one 50 kg cement package for consistency.

- Achieve a homogeneous mix by adding three packages of PERLISIOL, which may appear dry but will reach the desired plasticity upon thorough mixing.

- Expect a reduction in volume (5-10 cm sinking), and if necessary, incorporate up to 10% natural sand in the final step to adjust the mixture.

Following these guidelines ensures that PERLISIOL P-12 is ready for use, providing the industry-leading insulation and lightweight properties

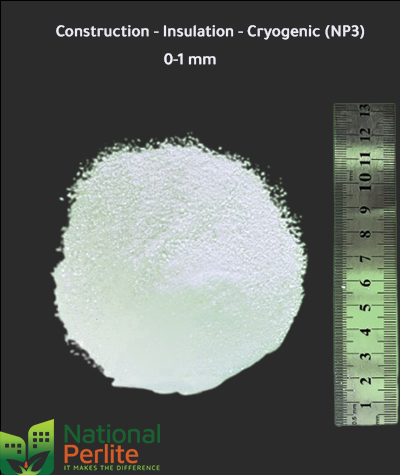

Technical Features

| Attribute | Values |

|---|---|

| Density | 50 -60 kg/m3 (+-%10) |

| Grain Diameter | 0-1 mm |

| Chemical Composition | 0,040-0,045 Kcal/ mhC |

| Fusion Point | SiO2 %74 Al2O3 %14 Na2O %3 K2O %5 MgO %0.5 CaO %0.5 Fe2O3 %1 Not effected from acids and alkalines. PH-7 |

| Package | Alkali Oksitler Aksit ve Alkalilerden etkilenmez |

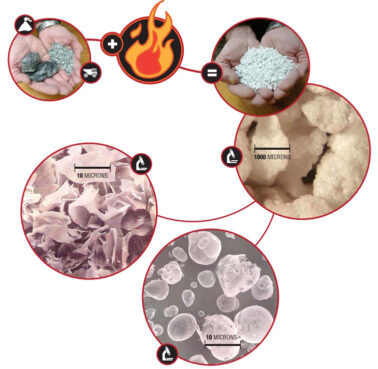

Why Perlite Is Effective: A Scientific Perspective

Perlite’s effectiveness is rooted in its unique physical properties. When heated to approximately 900°C (1,700°F), perlite’s volcanic glass softens, and its internal water vaporizes, causing an expansion that transforms the rock into a lightweight, porous material.

Versatile Functionality:

- Insulation: The expanded form of perlite consists of micro-bubbles, creating an insulative material that traps air and reduces thermal conductivity. This feature makes it ideal for insulation in the construction industry.

- Filtration: These same micro-pores effectively filter out impurities, making perlite an excellent filtration aid for liquids in various sectors, from food and beverage to wastewater treatment.

- Horticulture: In gardening and agriculture, perlite’s air pockets retain water and provide space for air, promoting root growth and improving soil structure without compaction.

- Industrial Uses: Perlite is also incorporated into lightweight plasters, concrete, and refractory materials, improving strength while maintaining a lighter weight.

- Consumer Products: Its gentle abrasiveness and absorbency make perlite a useful component in personal care products like exfoliants and a carrier in cleaning supplies.