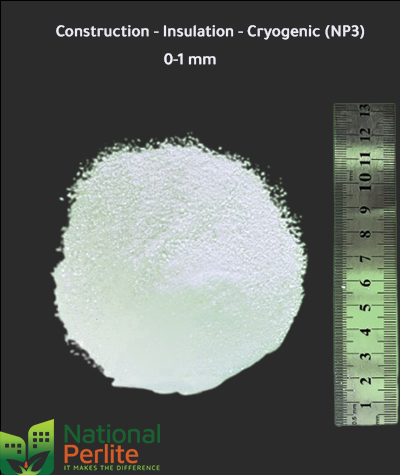

Construction – Insulation – Cryogenics (NP3)

|

NP3 |

|

|

Attribute |

Values |

|

Density |

40-50kg/m3 |

|

Grain Diameter |

0-1 mm |

|

Thermal Conductivity |

0,040-0,045 Kcal/ mhC |

|

Chemical Composition |

SiO2 %74, Al2O3 %14 Na2O %3, K2O %5 MgO %0.5, CaO %0.5 Fe2O3 %1, Ph=7 Not affected by acidsand |

|

Fusion Point |

1200 C |

|

Packages |

0,1-1m3 |

NP3 on Construction and Building Materials

In the realm of construction and building materials, perlite has established itself as a versatile component, essential for modern building techniques. It is a key ingredient in creating lightweight concrete, enhancing not only the insulating properties but also the structural integrity of concrete used in both readymix and precast applications. Beyond its role in concrete formulations, perlite is a favored choice as a loose-fill insulation material for concrete masonry blocks, enhancing thermal efficiency in cavity walls and residential homes. Its adaptability extends to specialty applications such as fireproofing sprays, chimney fills, interstitial floors, and acoustical treatments, offering solutions that meet the rigorous demands of the construction industry.

Benefits of Perlite in Construction

- Superior Thermal Performance: High insulating values contribute to energy efficiency in buildings.

- Fire Resistance: Non-combustible nature offers superior fire ratings for safer construction.

- Lightweight Yet Durable: Facilitates ease in handling and longevity in structural applications.

- Smooth Slope-to-Drain Surface: Provides a monolithic surface for better water management on roofs.

- Versatile Roofing Material: Can be nailed or glued, offering flexibility in roofing applications.

- Wind Uplift Resistance: Meets Underwriters Laboratories (UL) and Factory Mutual (FM) criteria for wind uplift, enhancing building resilience.

- Innovative for Cellular Concrete: Improves cellular concrete through hybrid technology, adding to its strength and functionality.

- Cost-Efficiency: Realizes savings in time, labor, and materials, optimizing construction budgets.

- Acoustic Insulation: Reduces sound transmission for quieter indoor environments.

- Environmental Sustainability: Contributes to eco-friendly building practices and certifications.

- Versatility in Application: Perlite can be used in various forms, such as loose-fill, rigid board, and foam, offering flexibility in design and application for different construction needs.

- Compatibility with Other Materials: Perlite can be combined with cement, gypsum, and other building materials, enhancing its utility and functionality in composite systems.

- Ease of Handling and Installation: Due to its lightweight nature, perlite is easy to transport, handle, and install, reducing overall construction costs.

- Moisture Resistance: Perlite’s non-absorbent nature helps prevent moisture-related issues like mold and mildew.

- Chemical Inertness: Maintains performance in various environments due to its resistance to chemicals.

Insulation

The remarkable expansion of perlite ore, when subjected to rapid, controlled heating, not only multiplies its volume up to 20 times or more but also imparts it with exceptional insulating properties. This volumetric increase creates a complex internal structure within each perlite particle, consisting of numerous tiny air cells that dramatically reduce heat transmission. The expanded perlite thus becomes an outstanding thermal insulator, contributing significantly to energy conservation in buildings. It also serves as an effective sound barrier, dampening noise transmission through masonry walls. These characteristics make expanded perlite an indispensable material in constructing energy-efficient and acoustically sound residential and commercial spaces.

Benefits of Perlite in Insulation

- Thermal Efficiency: Perlite’s unique cellular structure provides outstanding thermal insulation, reducing energy costs associated with heating and cooling.

- Sound Insulation: Its porous nature helps absorb sound, aiding in acoustic insulation and creating quieter indoor environments.

- Fire Resistance: Non-combustible and able to withstand high temperatures, perlite enhances the fire safety of insulated materials.

- Lightweight: Expanded perlite is light, which simplifies transport, handling, and application, and places less stress on structural supports.

- Moisture Resistance: Perlite is hydrophobic and does not absorb moisture, mitigating the risk of mold, fungus, and mildew in insulation systems.

- Eco-Friendly: Extracted with a minimal environmental footprint, perlite supports sustainable construction practices.

- Energy Savings: The durability and effectiveness of perlite insulation provide long-term savings on energy and maintenance costs. Investment will quickly pay back the cost of the insulation and will decrease building heating and cooling costs for years to come.

- Non-Settling: Perlite retains its insulating properties and volume over time, unlike other materials that can settle or degrade.

- Chemically Inert: It remains stable and does not react with most chemicals, ensuring longevity and consistent performance.

- Versatile Applications: Suitable for use in loose-fill, rigid board, spray-on applications, and within concrete and plasters.

- Ease of Installation: Its versatility and ease of use make it applicable for new builds, retrofits, and complex architectural designs.

- Sustainable Practices: Perlite supports sustainable building practices, contributing to LEED certification and other green building standards due to its natural and low-impact production process.

Cryogenics

Cryogenics involves the production and behavior of materials at very low temperatures, typically below -100 degrees Celsius. Our cryogenic perlite is engineered to provide unmatched insulation in cryogenic tanks, where maintaining the stability of liquid gases is critical. By filling the interstitial spaces between double-walled vessels, perlite maintains the necessary low temperatures to keep gases in their liquid state, even at extreme lows of -270 degrees Celsius.

Benefits of Perlite in Cryogenics

- Non-Settling Characteristics: Perlite insulation tends to maintain its original volume and insulating effectiveness over time, unlike some other materials that can settle or compact, leading to diminished performance.

- Low Moisture Retention: Perlite’s hydrophobic nature means it absorbs very little moisture, which is critical in cryogenic applications where the presence of moisture can significantly impact insulation effectiveness.

- Chemical Inertness: Perlite does not react with cryogenic fluids, ensuring that it does not degrade or off-gas, which could otherwise contaminate the stored substances.

- Ease of Installation and Reusability: Perlite can be easily installed in cryogenic systems, and when systems are de-commissioned or serviced, perlite can often be collected and reused.

- Cost-Efficiency: The use of perlite often results in cost savings due to its natural abundance, ease of installation, and low maintenance requirements.

- Environmental Safety: Perlite is a naturally occurring material that is mined and processed with minimal environmental impact, making it a safe choice for cryogenic applications.

- Compliance with Industry Standards: Perlite often meets the strict industry standards required for cryogenic insulation materials, ensuring reliability and safety in sensitive applications.